TIFTUF AT THE SWAMP: LAYING THE FOUNDATION FOR EXCELLENCE

By Julie Holt

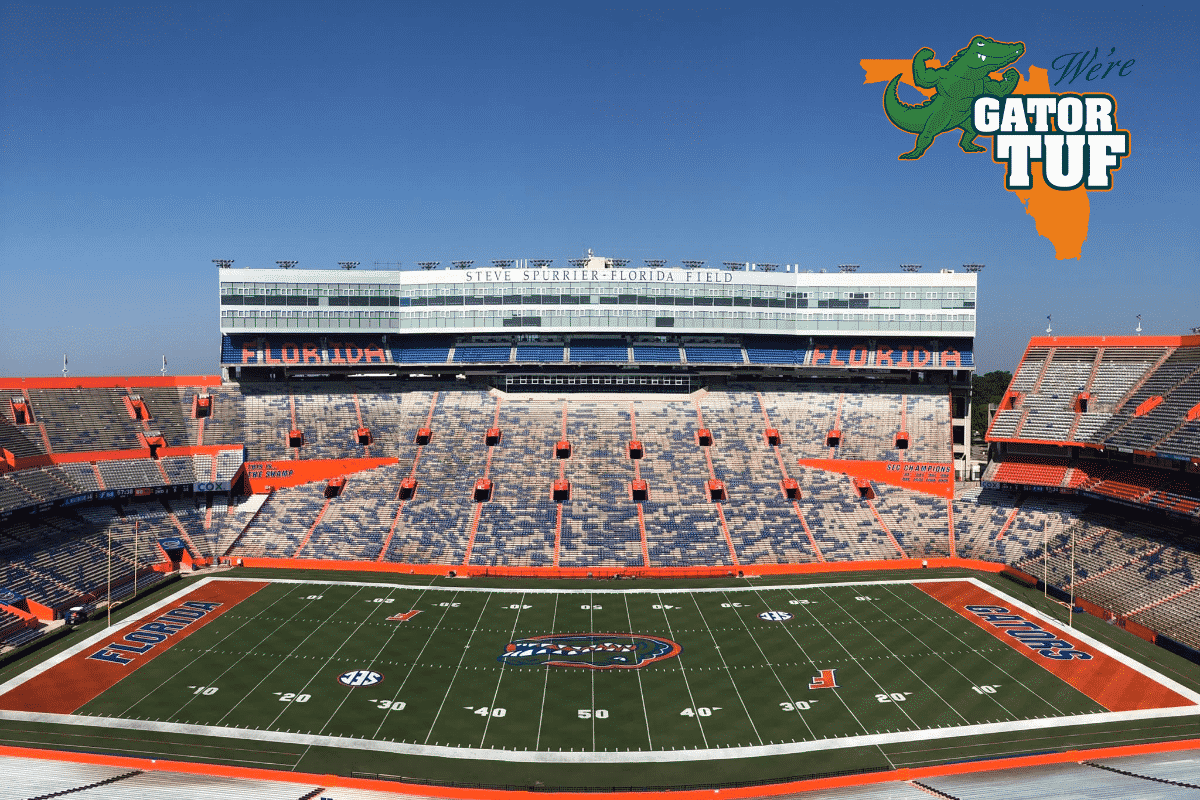

The Swamp.

Just the name evokes a visceral reaction from every college football fan in the south. Florida Gators beam with pride at the mention of their legendary stadium. Other SEC teams’ fans may respond with less enthusiasm, but no one can question the fact that Steve Spurrier-Florida Field is an iconic place to play college football.

The statistics don’t lie – three national titles, eight conference titles, three Heisman trophies and many winning seasons attest to the Florida Gators’ dominant football program. And for every football team that plays on such a big stage, there’s always an unsung hero, a hero that endures the elements and injury, is pushed to its limits, yet expected to perform week after week, year after year—the field.

Most fans never give it a second thought. Even players and coaches seldom notice this integral part of the game unless it isn’t performing. But turfgrass managers recognize the field as the very foundation of a top-tier NCAA football program. It is this recognition of the importance of the playing surface that drives sports turf managers across the country and beyond to seek the most functional and attractive turfgrass available for their sports fields.

Researching Renovation

In November of 2018, when Jason Smith, director of sports turf at the University of Florida in Gainesville, saw the events calendar for Spring of 2019 at Ben Hill Griffin Stadium (aka The Swamp), he knew it was time to start planning a field renovation. Smith says, “The Garth Brooks concert was scheduled for Saturday, April 20, with graduation two weeks later, which would have the field covered for another six to eight days. The time and costs involved in removing the flooring and reinstalling it By Julie Holtbetween the two events were excessive for the little time we’d gain. With the grass covered for nearly a month, total renovation was the best solution.”

Jason Smith started his position with UF in November of 2012. The Swamp had been renovated that July with Celebration Bermudagrass installed. He observed the last home game and notes the field was “pretty beat up” from that season. In early December, the strength coach had his players pushing sleds down the middle of the field at the South end, the most worn area where most of the traffic was concentrated anyway. “In February of 2013, we resodded that section, from the Gator head to the south between the hashes. Even when the coaching staff was using the game field for many camps and practices, it held up well. We did resod to replace the painted areas in the endzones and the Gator head section one year, but that’s the only resodding we’d done.”

Smith was making that happen with overseeding. He says, “We’d normally have a bye week before the Georgia game, followed by two away games, so I’d have a good three weekends to get the perennial ryegrass overseeding in before the team was back on our field. Then we’d have two to three games back to back to finish the home season.” Typically, the Gators would have a practice or two on the game field before the spring game. Smith says, “So I’d leave the overseed in place to protect the Bermuda and then spray the ryegrass out right after the game to give the Bermuda time to recover.”

When Coach Dan Mullen took over in November of 2017, use of the game field was cut back. “Coach and his staff are great to work with,” says Smith. “They only hold a few scrimmages on the game field before we get into game mode. They even start the season, with what used to be called two-a-days, on one of our recreational sports fields that we prepare for them. It gives them a different venue and it saves our practice fields.”

With the renovation, Smith knew he wanted a grass that would look as good in the fourth quarter as it did at the beginning of the game and would have a good recovery rate and the wear tolerance to sustain field quality throughout the rigorous season.

After researching and narrowing the field to three varieties that might uphold the standard expected of a high-level SEC stadium, Smith made a visit to the university turfgrass program’s research site. Dr. Jason Kruse, of Florida assistant professor and turfgrass specialist, showed Smith the research plots. Nematodes are a major challenge for turfgrass managers in Florida, so when Smith saw that TifTuf had such a low incidence of nematode damage, his interest was piqued.

“What really caught my eye was the nematode tolerance plots,” says Smith. “TifTuf had absolutely no off color or thinning. Next to the other plots, it was really impressive. Nothing can really stop the nematodes effectively but TifTuf ’s aggressive rooting helps it combat them.” Upon learning of other features of TifTuf—staying green later in the season than other Bermudagrasses, excellent wear tolerance, increased drought tolerance—Smith was certain he’d found the right fit.

The Road to Excellence

It is easy to recognize what makes a turfgrass variety a great choice for certain uses, but we rarely get a peek into how that specific variety came to be. As new cultivars are introduced with increasing regularity, it is important to understand what goes into the making of that brand, especially when the stakes are this high.

TifTuf ’s recent entry onto the warm-season turfgrass scene is remarkable, and while it may seem like an overnight sensation, many years of evaluation and development went into establishing this variety as a top performer.

Developed by the experts in Tifton, Georgia, TifTuf was 20-plus years in the making. “It’s important that we studied this in Georgia, but we had bigger plans for TifTuf,” says Dr. Brian Schwartz, associate professor at the University of Georgia and TifTuf breeder (alongside Dr. Wayne Hanna). “It’s very important to do a lot of testing to make sure you don’t release a product that gets out to the public and fails.”

After a painstaking breeding and development process, it was clear that this grass would be a great success if it was brought to market properly. Enter The Turfgrass Group, a licensing and marketing company made up of turfgrass professionals. The team at The Turfgrass Group recognized TifTuf as a superior product and began implementing their unique strategy to ensure that this variety would provide the exceptional performance it had shown in trials.

For the high quality that is demanded at The Swamp, it is essential that the variety chosen perform consistently and predictably under intensive management strategies. With its initial release, all TifTuf plant material was sent directly from Georgia Foundation fields to licensed and Certified sod farms, ensuring consistency in sod production. A second source was later added in California, a first for any UGA variety. This source continues to follow the rigorous standard set in the eastern U.S., while allowing wider-spread distribution in the western part of the country. Every one of the 60 U.S. sod farms and 42 Australian farms that produce TifTuf get it from one of those two sources, guaranteeing purity in over 6,000 acres of TifTuf grown in the U.S., plus hundreds more in Australia.

Prior to planting, a state Crop Improvement Association inspector sees every field and must approve it before TifTuf is planted. The history of the field is reviewed, and if it meets Certification standards, approval to plant is granted. But this is just the beginning of the quality assurance process. Once planted and growing, every square foot is visually inspected by The Turfgrass Group two to three times per year.

“With our continuous inspection of TifTuf, we’re ensuring genetic purity,” says Bill Carraway, vice president of sales and marketing at The Turfgrass Group. “We’re going to spot anything that’s not TifTuf, but our primary focus is on off-type Bermudagrasses. At times, it’s like looking for a needle in a stack of needles.” It is this rigorous process that has led to TifTuf ’s success. Carraway says, “It has been licensed to more farms in less time than any licensed proprietary cultivar in history.”

Technical Expertise and Superior Product

Choosing the right grass is only the first step of many in field renovation. Smith reports they took multiple samples around the field and found an average of eight to nine inches of heavy, dark organic buildup. He says, “We wanted to get back to the original construction grade.” Smith contracted with the Laserturf team, headed up by Joe Peters, for the renovation project.

“Once we had committed to the TifTuf, Joe Peters got us connected with Pike Creek Turf,” says Smith. “He knew their high standards from working with them on previous projects and knew they were a TifTuf grower.”

Jaimie Allen of Pike Creek Turf reports they care for sports field grasses differently in mowing, topdressing, fertilization, basically managing that segment of their production as it would be managed on the field. They understand the needs of the customer segments they serve and fine-tune their management programs to meet those needs. The process starts from the selection of the grass varieties they grow and continues throughout the entire process—from establishment, through onsite management, harvest, delivery and installation, whether that installation is handled inhouse or by one of the many specialized contractors they also serve.

When Jason Smith came to visit the farm, the sod designated for the Swamp was already within that aggressive management program. Company founder, Jimmy Allen (Mr. Jimmy), greeted Smith onsite and gave him the tour of the farm that included a visit to his grass.

Jaimie Allen says, “We understand that changing a grass variety on their playing field is a big decision for a sports field manager. Once they make that decision and commit to making the purchase, it becomes their grass in their minds and in ours. Our role is to work with them to make sure our management of the grass while its growing at our farm will provide the product they want when it arrives at their field.”

After that site visit, Bruce Allison, sales/horticulturist for Pike Creek Turf, was Jason’s primary contact. Allison says, “Sports field managers and golf course superintendents know what they want in performance from the grasses they select for their facilities and we work with them to make sure the grass is ready to meet those performance standards when it is delivered and installed. And we follow up with them once the grass is in place, under their management program, to ensure it is performing well.”

Smith was the first sports field manager to select TifTuf from Pike Creek, though it has been installed on other athletic fields across the U.S. provided by other growers. Carraway says, “In its first three years in the marketplace, TifTuf has been installed on over twenty professional and collegiate sports fields and has earned recognition in two sports field of the year awards.” Dell Diamond, under the management of Nick Rozdilski, earned Texas Turfgrass Association Field of the Year honors and MoneyGram Soccer Complex, under the management of Troy Crawford, earned the Sports Turf Managers Association Field of the Year award.

Getting It Done

The looming deadline for having a usable field was Friday Night Lights, a football camp for high-school age players held at the Swamp in late July. Smith says, “It’s a huge event. We have 10 or 12 different stations set up on the game field and several hundred kids go through each one.”

Smith and the Laserturf team tackled the renovation. After stripping away the existing sod, they ended up taking out 14 inches of material and bringing back in four inches to correct the field profile and drainage and to create the best possible foundation for the Gators’ new field.

Smith says, “We planned the process allowing time for the new sod to get rooted, so I opted for the thinnest sod cut that would still retain good tensile strength, to bring in as little outside soil as possible.” Allison adds, “Our long-term background working with Joe and Laserturf was a factor there, giving Jason reassurance that we would provide the sod with the consistent precision cut he wanted.”

Flexibility came into play, too. The renovation extended across the stadium, wall to wall, with just under two acres of sod, 87,000 square feet. The installation was planned to begin on Wednesday, but Smith says, “Looking ahead at the weather forecast, we bumped that up to Monday, June 10. Pike Creek handled the sod harvesting and delivery; Laserturf handled the installation. Once the trucks started rolling, they kept coming. All the sod was down by late night on Tuesday. They were just doing a bit of trimming to wrap up on Wednesday when the rain started, and it rained for two days afterward. The timing was perfect.”

Looking Ahead

TifTuf performed as Smith anticipated throughout the football season. “After games, repair was minimal and recovery was excellent,” he says. “This year, after the Vanderbilt game, we had two weekends off, but the TifTuf was retaining its color and holding up well, so I didn’t overseed. It looked good and played very well for the Florida State game. I was super excited to have so much Bermudagrass going into the off season.”

Winter started off warmer than usual, with lows around 68 to 70 degrees F, and the field was looking great, maintaining fall color and continuing recovery of divots, even though the shorter day length was telling the Bermuda to shut down, Smith reports. “I’d estimate it at about 90 percent cover.”

The week of January 20, temperatures dropped to 29 degrees one morning and 30 the next. Temperatures were hovering in the 60s, with little sunlight and high humidity. Smith says, “Because the field is a huge recruiting tool and potential recruits would be coming in, I applied a hint of colorant to the field, enhancing it just a bit. I got a few responses on Twitter about how good it looked from folks heading to Orlando for the Golf Industry Show (GIS). Darkening the leaf blade also draws the heat, which will increase the speed of recovery from the cold as temperatures warm. I’m very excited about how it will look and perform next season.”

The Gators have confirmed their status as a leader in the fiercely competitive SEC, and every element of the team’s performance is under scrutiny for the top caliber performance that is expected at this level. While the collective efforts of over 80,000 fans may help drive the team to victory on game day, the solid foundation of an exceptional playing surface may just be the ultimate champion.

Julie Holt is content director for TheTurfZone.com and managing editor of Leading Edge Communications, LLC. She can be reached at Julie.leadingedge@gmail.com. Photo courtesy of Jason Smith